Hand Applied Plaster Application Manual

Uni-Finish is modified gypsum finishing plaster for use on wide range of backgrounds. It provides a smooth and high quality surface to internal walls and ceilings.

Recommendation

Objective: Recommendations for Application Activity

- Wear proper working clothes and gloves

- Examine the application surface

- Calculate the effective working area

- Calculate the amount of Insulate and Uni-finish

- Calculate the total amount of water needed

- Check application conditions

- Clean and damp the surface if necessary

- Follow the mixing procedure of Insulate and Uni-finish as described in this manual

- Correct the surface if necessary

- Care must be taken for details

- Use time and product efficiently

- Learn how to place the liners

- Apply Insulate on the walls

- Apply Insulate on the ceiling

- Apply Unifinish on the walls

- Apply Unifinish on the ceiling

- Follow ethical rules of your profession

- Be sensitive to protect the environment

1. Preparation of the Application Surface

Objective: To apply Insulate and Uni-finish according to manufacturer recommendations before the application, the surface must be checked;

- All foreign sticky materials, such as dirt, soot, mortar stains, concrete dirt, molding wood wastes

- Loose and spilled parts on concrete surface

- Sticky lime and efflorescence

- Very smooth and tight surfaces

Visual control

Manual control

- Control of the surface by hand if it is dusty and dirty from different areas

Scraping control

- Check if scaly parts or loose sands are present by spatula or trowel scrap

Wetting control

- After application of water on the surface, checks if water is always present, it may have some oil on the surface or it may be too humid.

Temperature control

- Check before the application if the environment temperature is less than 45 degree Celsius

2. Insulate Application

After inspection of the surface and taking necessary precautions one can start the application Insulate. Aluminum liner for the corners, Aluminum liners for the wall thickness, and galvanized steel mesh for the joints are required.

The list of tools are plastic container, mechanical mixer, water gauge, plastic plaster shovel, plaster trowel, aluminum knife template, special plaster sponge, rectangular steel trowel and Spatula.

Before mixing, follow the technical specification of Insulate.

| Technical Specifications for Insulate | |

|---|---|

| Water/Powder Ratio | - 18-18.5 lt per one bag of 35 kg |

| Working time | - 60 minutes |

| End of Setting time | - 120 minutes |

| Consumption | - 18-18.5 lt per one bag of 35 kg |

| Technical Specifications for Uni-Finish | |

|---|---|

| Water/Powder Ratio | - 16,5-17,5 lt per one bag of 25 kg. |

| Working time | - 60 minutes |

| End of Setting time | - 130 minutes |

| Consumption | - 1 kg per m2 for 1 mm of thickness |

The application must be performed according to gypsum standards and gypsum specifications by choosing proper products. DO NOT add water on powder. DO NOT add water more than 75% of the product weight. Use always protective gloves and follow Health and Safety rules.

Mixing

1. Necessary amount of water is poured into the container. Attention should be paid to the cleanness of gypsum container and water, which has a high impact on the performance of plaster.

2. Insulate bag is cut off by a cutter.

3. Insulate is poured slowly into the container; care should be taken not to have big lumps in the container. 18 kg of water is enough for one bag, but if it is not the case, pour INSULATE until it covers the entire water surface.

4. Wait for a couple of minutes until the ingredients in the powder are wetted.

5. Start mixing with a low speed mixer. High cycle increases plaster consumption and leads to such problems as early hardening etc.

7. The mortar in the plastic container can be used in 1 hour

8. Do not add more water or powder at the END of mixing.

Wall Application

1. The cracks and holes on the surface should be repaired.

2. Insulate is applied to the joint of different material by using galvanized steel mesh.

3. Install the corner liners properly on the wall by using the mortar in the container.

4. Install thickness liners at every 150-200 mm. Care should be taken that the liners are aligned and water gauged

5. After the mortar of the liners is hardened, the mortar in the container is taken on a plastic plaster shovel by using a trowel.

The plaster mortar on the trowel is sprinkled on the wall. The application is continued until the surface is covered with this method. Nature of the surface does no change the form of application. Application is done in the same manner on brick, concrete, gross concrete, aerated concrete, hollow brick etc. surfaces.

6.Apply the aluminum knife template from bottom to upwards by pressing the liners.

Excessive mortar on the aluminum knife template will be applied to empty gaps on the wall surface.After applying a second and/or third knife template the surface is finished

7. After around 40 minutes from the initial application, the thickness liners are taken away and empty space is filled with mortar by using a trowel.

8. After around 50 minutes from the initial application, the surface is levelled again, and if necessary 2-3 mm of mortar will be applied on the surface in order that it is gauged vertically and horizontally.

Wall Finishing With Method A.

1. In order to finish the surface fast, surface is left as it is; if a smooth surface is needed, the next item is followed.

2. When the surface is dried, Uni-finish mortar is prepared according to the specifications and application rules and it is applied on the surface by a steel trowel and a spatula

Wall Finishing With Method B.

1. In order to finish the surface more properly, a special plaster sponge is used after 50 minutes of the initial application. The satin of the gypsum mortar is taken on the surface.

2. Then a rectangular steel trowel is used 5-10 minutes after sponging until a smooth surface is obtained.

3. If a smoother surface is needed, Uni-finish is applied as in the Method A.

note: The final Surface will be as in this picture

Ceiling Application

1. It is exactly the same as wall application, but in this case instead of sprinkling the mortar, it is applied by pressing the special plaster shovel upwards through the ceiling.

2. The rest of the procedure is followed as in the previous section.

Powder & Water Consumptions

Objective: To calculate the amount of Insulate and Uni-Finish in a site the specification of INSULATE is as follows;

| Technical Specifications for Insulate | |

|---|---|

| Water/Powder Ratio | - 18-18.5 lt per one bag of 35 kg. |

| Working time | - 60 minutes |

| End of Setting time | - 120 minutes |

| Consumption | - 10 kg per m2.cm |

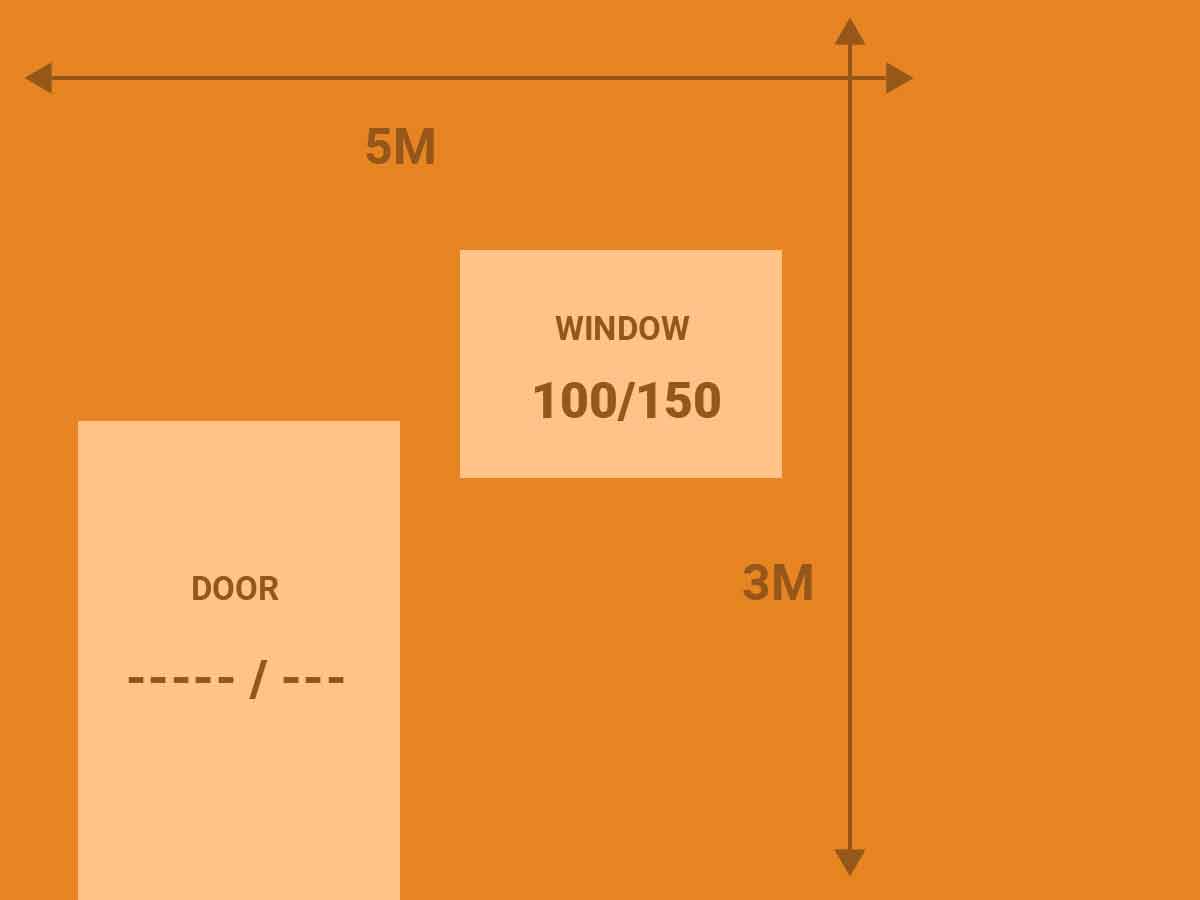

→ The total area is 5 x 3 = 15 m2

→ The empty areas of the window and the door are (0.9 x 2.1) + (1 x 1.5) = 3.39 m2

→ The net area is; 15 – 3.39 = 11.61 m2

→ If a thickness of 1 cm will be applied, then;

11.61 x 10 = 116.1 kg of Insulate is needed.

→ If the thickness of plaster is 1.5 cm, the total amount will be calculated as following;

→ 116.1 x 1.5 = 174.15 kg Insulate (5 bags)

→ The total amount of water needed is;

5 bags x 18 = 90 liters of water

→ It will be the same calculation for Uni-finish according to its specification

Contact Us

Frimex Plaza, 3rd Floor,

9105 Ibrahim Al-Juffali Street,

Al-Andalus District

Jeddah 23326-3764,

Saudi Arabia- +966 9200 220 28 +966 12 66200 72

Yanbu Factory address: Light Industrial Park 6th Street – Yanbu, KSA.

Yanbu Factory address: Light Industrial Park 6th Street – Yanbu, KSA.

+966 (14) 3254888 – 9200 220 28

You can call us or leave a request here. We are always glad to see you in our office from 9:00 to 18:00.

reach us on email:

info@global-gypsum.com

View Map